The Impact of Micro-channel Condenser Technology on Fuel Efficiency in Heavy-Duty Trucks.

- kaibin Li

- Jan 10

- 2 min read

The Impact of Micro-channel Condenser Technology on Fuel Efficiency in Heavy-Duty Trucks

In the highly competitive heavy-duty trucking industry, every drop of fuel counts. As fuel prices fluctuate and environmental regulations like the EPA and Greenhouse Gas (GHG) standards become stricter, fleet managers are looking for every possible edge. One of the most significant yet overlooked advancements in this area is the shift to Micro-channel technology in truck condensers.

How exactly does a refrigeration component affect the fuel tank? Let’s dive into the science of thermal efficiency and its impact on your bottom line.

1. What is Micro-channel Technology?

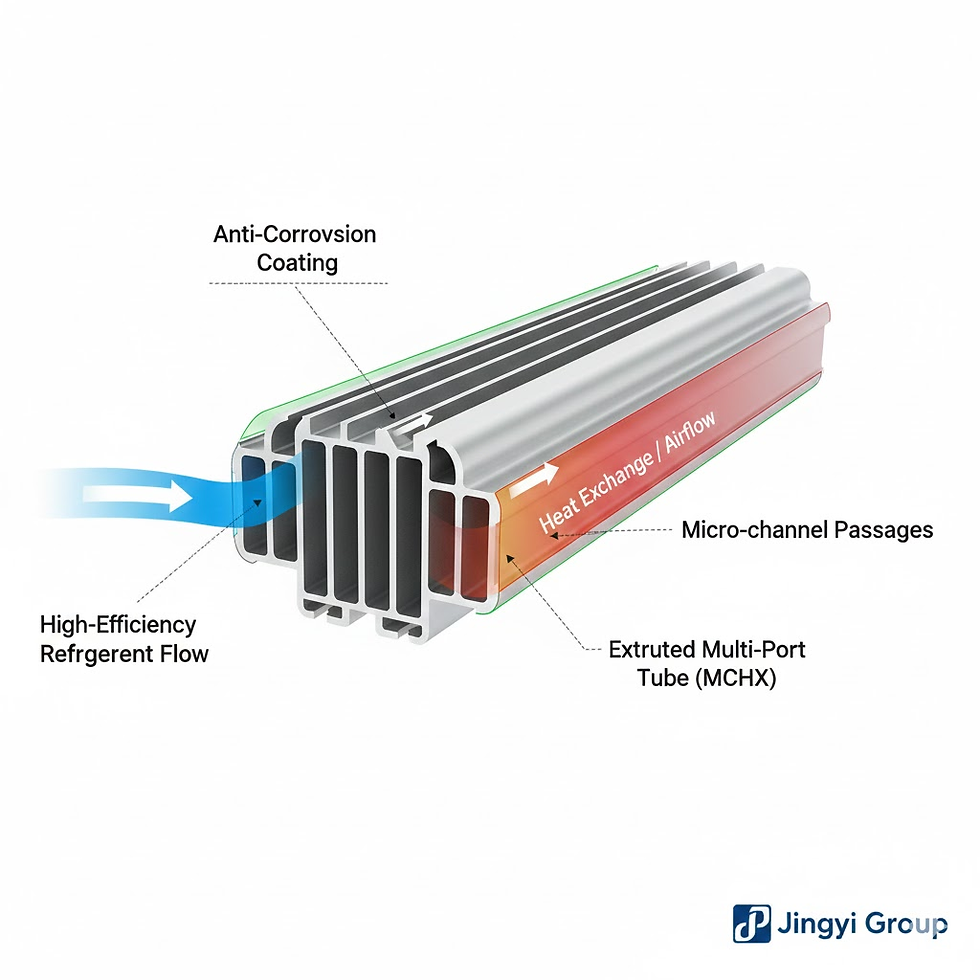

Traditional tube-and-fin condensers have served the industry for decades. However, Micro-channel heat exchangers (MCHX) use flat, multi-port aluminum tubes. This design significantly increases the surface area for heat transfer while reducing the overall footprint of the unit.

At Jingyi Group, our micro-channel truck condensers are engineered to maximize airflow and thermal exchange, which provides a ripple effect of benefits for the entire vehicle.

2. Reducing Engine Load and Fuel Consumption

The condenser’s job is to reject heat from the refrigerant. The more efficiently it does this, the less work the compressor has to do.

Lower Head Pressure: Micro-channel technology allows the system to operate at lower discharge pressures. This reduces the torque required by the engine to drive the AC compressor.

Reduced Fan Usage: High-efficiency heat rejection means the engine cooling fan (which consumes significant horsepower) runs less frequently.

By reducing the parasitic load on the engine, a high-quality truck condenser can contribute to a 1% to 2% improvement in overall fuel economy—a massive saving for long-haul fleets.

3. Lighter Weight, More Payload

Weight is the enemy of fuel efficiency. Micro-channel condensers are made entirely of aluminum and are significantly more compact than traditional copper-tube models.

Up to 30% Weight Reduction: Switching to an all-aluminum truck condenser reduces the front-end weight of the truck.

Smaller Refrigerant Charge: Because the tubes are so small, the system requires up to 40% less refrigerant. This not only lowers maintenance costs but also reduces the environmental impact in case of a leak.

4. Durability for Harsh Environments

Whether you are navigating the freezing winters of Canada or the dusty roads of South Africa, durability is key.

Our micro-channel units at Jingyi Group feature a single-material (all-aluminum) construction. This eliminates the galvanic corrosion that often occurs between copper tubes and aluminum fins, ensuring your heavy-duty truck condenser lasts longer and maintains its efficiency throughout its service life.

Conclusion: A Small Change with Big Returns

Upgrading to micro-channel technology is one of the smartest investments a fleet manager can make. It’s a rare "triple win": you save on fuel, reduce your carbon footprint, and lower your maintenance costs.

Is your fleet optimized for the road ahead? Explore Jingyi’s Micro-channel Truck Condenser Range and start saving on fuel today.

Comments